Modeling Tutorial: Making Larger Bases

A quick tutorial showing you how to make larger bases:

One of the issues with the Old World has been the availability of product. It is now two full months since the January 20th launch date, and the core rulebook is STILL out of stock, along with many other items, including the larger base sizes. If, like me, you have a collection of older models that you want to re-base for The Old World, you might be struggling to find bases for them.

Fortunately, most of the larger bases are in equal increments of the smaller bases, meaning they can be tiled together to create the larger sizes. In this tutorial, I'll show you how to tile the bases together and fill the joins so that, once painted and based, it will look like a single, solid base.

The first thing you need to do is grab a handful of bases to be tiled together. I'm making 75mm x 50mm bases for my Tomb Scorpions, but you could also use this process to tile four bases into a 50mm x 50mm monster base, or two bases into a 25mm x 50mm cavalry base. You could also tile two of the 30mm infantry bases into a 30mm x 60mm heavy cavalry bases.

The key to holding the bases together is mounting them in styrene card. In order to not add too much thickness to the bases and maintain a consistent height with your other bases, use the thinnest card possible. I've chosen 0.25mm thick styrene from Evergreen Scale Models. It's a little thicker than a sheet of paper, and it comes in black so if the bottom edges of the finished base suffer any paint wear, it won't be as noticeable as if it was white styrene.

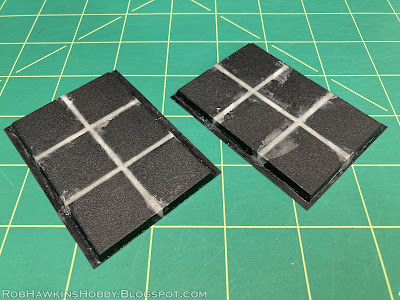

Start by tracing the bases with a pencil onto the styrene to give you a footprint of where each individual base will go. Apply a square of superglue and press one base in place. Then, apply more glue and press the next base alongside it. Do one side first, and use a steel ruler to ensure that the bases are perfectly aligned. Be as precise as you can, but work quickly so that you can get all the bases down before the glue dries. If you let the glue fully set up before placing the next base, the glue residue will create a slight elevation, preventing the next base from sitting completely flush and flat.

Once you have the bases glued down, you can trim away most of the excess styrene card and allow the glue to fully dry. Leave a little bit of a lip around the bases for now; we'll worry about the edge in a later step.

With the super glue fully cured, you can fill the gaps between the bases. I prefer Aves Apoxie Sculpt, but Milliput or brown Kneadatite putty will also work. The important thing is that whatever putty you use cures to a rock-hard finish, so it can be sanded smooth.

Be sure to get the putty all the way down into the recess, especially along the outer edges where it will be visible.

After the putty has hardened, use a knife to scrape the top smooth. The top doesn't need to be perfect because it will ultimately be covered with basing material. Use a steel ruler and a hobby knife to trim the excess styrene plastic around the edge of the bases. Get as close as you can to the base, but be careful not to cut into the sides at all. It's better to leave a little excess than to cut too close and chip the edge of the base.

To create a smooth, uniform edge, sand along the length with some standing sticks. Start with 180 grit to remove the excess styrene and smooth over the putty a bit. Then, move on to 320 grit to even everything out.

Work gradually so you don't gouge out too much material; you don't want to shave down the edges of the base. Move up to a 400 grit sanding stick to begin polishing the side of the base. Your goal is to get it so smooth that when you hold the base so the light glares on the smooth surface, you can't see any divots or lumps, and it looks like a smooth, uniform surface.

If you're having trouble getting it smooth, step down to a coarser grit to remove the imperfections, and then polish it with a finer grit. I took my bases all the way to 800 grit to get them nice and shiny.

That's all there is to it! A simple way to make sturdy bases with smooth, clean edges. If you were so inclined, you could even make cutouts in the bottom to expose the hollow underside of the bases if you wanted to insert magnets, for example.

Once I come up with a basing scheme, I'll be able to attach my scorpion to his new base. I just have to remember that the Tomb Scorpions go on their bases with the 75mm side facing front, even though the other way looks more correct. (I honestly have no idea why they chose to orient the model so it hangs way over the front and back edges with room to spare on the sides, when he clearly fits better lengthwise, and would be able to charge base-to-base without his claws getting in the way. But, what do I know? I've only been doing this for 27 years.)

'Til next time!

A very good idea with the bases, I do that in my models.

ReplyDeleteGlad you enjoyed the post! :)

DeleteAwesome I tried this and failed but omitted the crucial step of mounting on the styrene strip first!

ReplyDeleteThat's the key! I didn't do it for these bases, but you could also add a layer of the super thin card on the top for extra stability. (Just cut it a little smaller than the top so there's room around the edge, and the basing material will cover it.)

Deleteyou should get a resin and FDM printer and you can make all these fairly effortlessly... they're pretty cheap now too.

ReplyDeleteYeah, that's not what I do here.

DeleteIt could have been a good idea to use magnetic sheets insteed of styrene sheets.

ReplyDeleteI didn't want to add more height to the base, and magnetic sheet would have been too thick. Plus, since the magnetic sheet is a different material, it might not sand smooth and seamless with the plastic base, leaving a visible line around the bottom where the join was. (I like my models' bases to be clean and consistent throughout the army.)

Delete